Hotline:13861617077

|

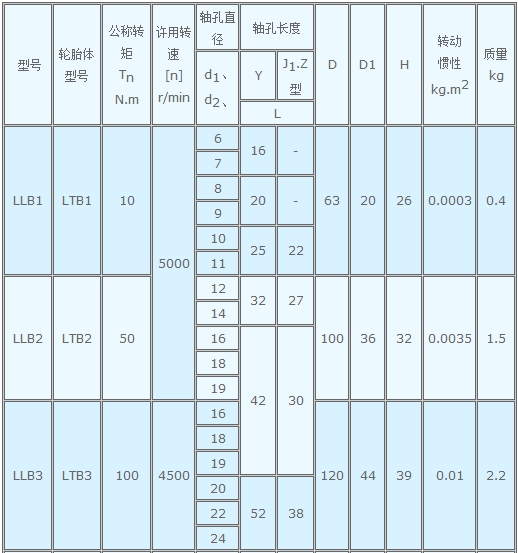

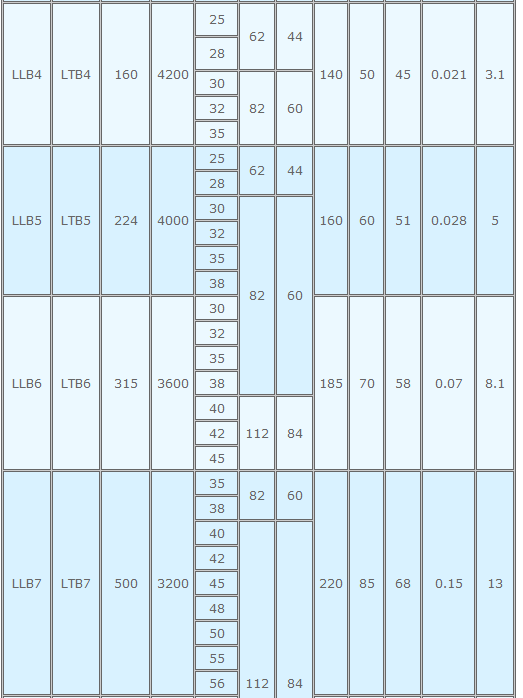

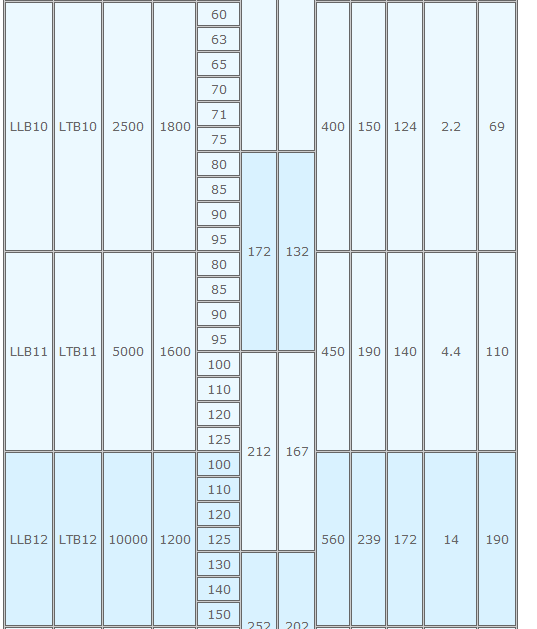

coupling with rubber type element

Tire coupling tire body is one of the spare parts of tire coupling, which is divided into UL, LA and LB tire body. Tyre coupling can be divided into convex and concave types. Convex type can be divided into three types: integral type with skeleton, integral type without skeleton and radial incision type. The inner side of the tire ring is bonded with the steel framework by vulcanization, and nuts are welded at the bolt holes in the framework. When assembling, the flange connection between the bolt and the two half couplings is used. The friction force between the tire and the flange end surface is transferred by tightening the bolt. The torsional shear deformation occurs when the tire ring works. Therefore, the tire couplings have high elasticity, great ability to compensate the relative displacement of the two axes, and good damping. Simple structure, no lubrication, assembly, disassembly and maintenance are more convenient. The shortcoming is that the bearing capacity is not high and the shape size is large. With the increase of the relative torsion angle of the two axes, the shape of the tire is twisted, and the axial size is slightly reduced. The additional axial force will be generated on the two axes, which will increase the bearing load and reduce the service life. When the tyre coupling runs at high speed, the outer edge of the tyre expands outwards due to centrifugal force, which will further increase the additional axial force. Therefore, when installing coupling, measures should be taken to make the stress direction in tire opposite to the stress direction generated during operation, so as to offset some additional axial force and improve the working conditions of coupling and two bearings.